CISDI 3R blast furnace showcases marked reductions in carbon dioxide emissions and costs

Date:2024/9/29 Source: CISDI

Striking environmental, economic and social benefits are resulting from the roll out of two world-first 3R Carbon-Hydrogen blast furnaces at Zongheng Steel Fengnan Plant in China’s Hebei Province.

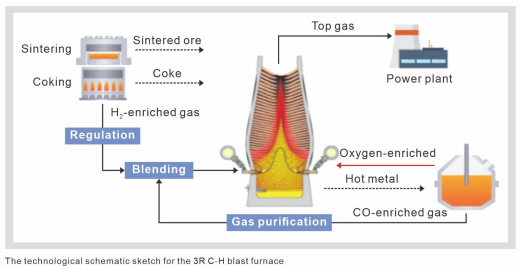

Achievements compared with China’s conventional blast furnaces of the same 2,300-cubic-metre volume:

• Solid fuel consumption reduced by 20 to 30kg per tonne of hot metal

• Mixed hydrogen and carbon monoxide gas replacement ratio ranges 0.50 to 0.57 kilogram per cubic metre in normal working conditions

• Carbon dioxide emissions during blast furnace production reduced by 5 to 10 per cent

• Smelting costs decreased by USD1.41 to 4.23 per tonne of hot metal.

These performance indicators were reached during the first year of operation.

The 3R Carbon-Hydrogen Reduction, Re-use and Recycle ironmaking tech lays a new pathway to economical and stable carbon emissions reduction at large blast furnace plants.

In July 2024, ground was broken on a project to create a further two Zongheng 3R C-H blast furnaces (at 2,000m3 level), and three more at a Jiangsu Province steel plant.

The world’s first 3R low-carbon blast furnace (2,000m3-level) demo at Zongheng Steel, Hebei, China

✧ Breakthroughs in theoretical study on carbon-hydrogen coupled intensified reducing

Long-term low-carbon ironmaking research has boosted CISDI’s theoretical foundation for intensifying the in-blast furnace reducing effect by coupling hydrogen and carbon monoxide.

Thanks to the team’s study on smelting basics and gas-solid flows and their massive analysis, simulation calculation and lab testing of iron oxide’s efficient reduction and low-carbon blast furnace operation, systematic C-H blast furnace ironmaking tech solutions have been formed.

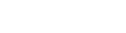

These solutions define the most favourable hydrogen concentration, the optimal proportion between hydrogen-enriched and CO-enriched gases, and an expert gas blending and blowing method in the smelting process.

✧ Safe, reliable equipment and digital applications for stable and smooth low-carbon blast furnace operation

The CISDI 3R BF has been operating smoothly since its startup, thanks to its innovative tech applications and the methodological foundation of carbon-hydrogen coupled intensified reducing.

Achievements:

⬥ Gas boosting and deep de-carbonisation

⬥ Collaborative gas and coal powder injecting

⬥ Smart regulation and control of furnace conditions

The gas decarbonisation system is demonstrating high standards of economy and efficiency. Removing carbon not only meets the recycled blowing requirement, but roots out mutual interference between carbon-recycling gas and the regulating of furnace conditions.

The innovative blowing and gas lance system relieves gas and coal powder’s interference in simultaneous combustion and enhances coal powder’s combustion efficiency.

It leads to stabler furnace conditions and safer blowing and injecting. The gas lance is designed to sustain safe and stable operation for a minimum of four months.

The 3R BF’s big data centre controls its entire operational data and is a basic platform for the development of an artificial intelligence-based multi-medium injection system.

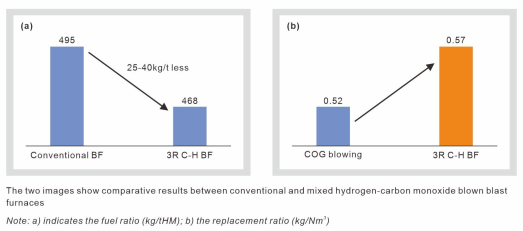

Compared with conventional BFs with the same burden design, it operates more stably and is more resistant to fluctuations in raw materials and fuels.

✧ Recycling byproduct gas at a blast furnace – basic oxygen furnace integrated mill opens new horizons for low-carbon smelting

Based on the integrated mill’s gas balance calculation and its systematic analysis, CISDI proposes to progressively use gas - the integrated mill’s byproduct - as a reducing agent instead of a heating and burning medium. Its new role of replacing part of the solid carbon to be consumed by BF smelting reduces carbon from the source.

A new technological flow has been created for combined carbon and hydrogen recycling throughout blast furnace, coke oven and basic oxygen furnace processes. This is a steel sector first and takes the perspective of flow metallurgical engineering and five-flow theories (iron, mass, energy, emission and smart application flows).

This method has opened up a new paradigm for integrated mill low-carbon smelting, transforming carbon recycling at a single blast furnace procedure to a method which operates throughout process flows.